Company

GLS is experience

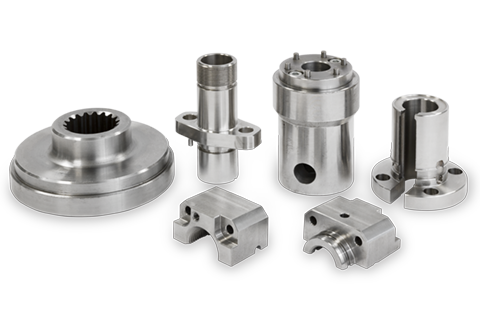

Our company has been operating for forty years in the creation of precision-turned and milled mechanical parts.

Our internal organisation means that we can satisfy our clients with small production or sample runs, as well as large-scale orders.

Experience, technology, innovation and constant investment in human resources over the years has allowed GLS to become a leading figure in the field of precision mechanics.

Quality

GLS is quality

Our prime goal has always been to achieve the highest level of quality for our products and processing. In 2019, we obtained ISO 9001:2008, guaranteeing the certified quality management system.

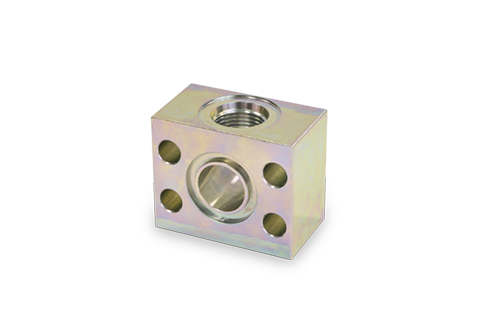

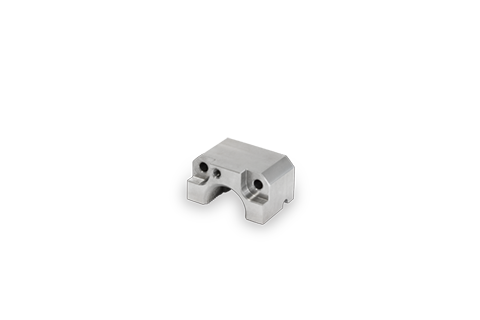

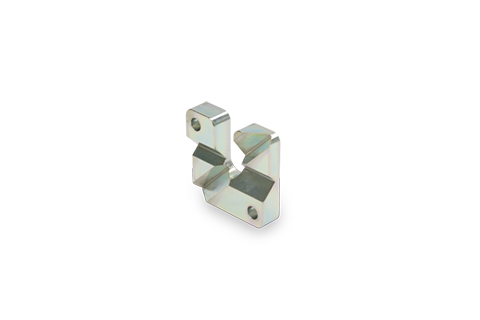

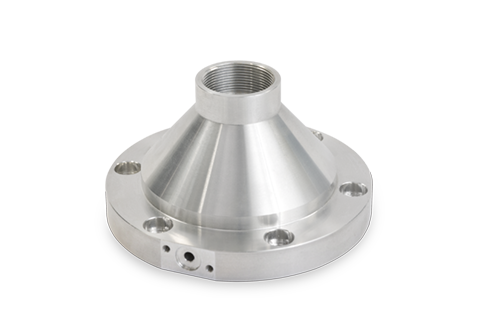

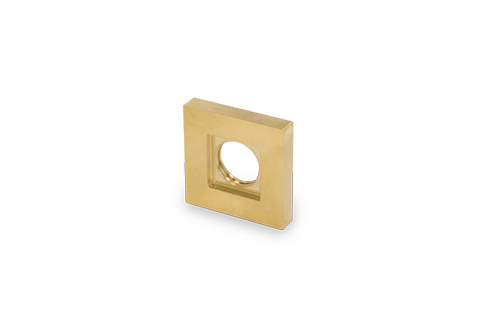

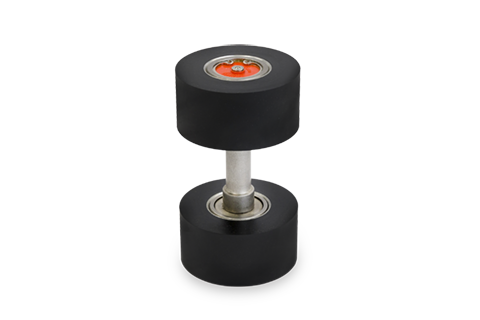

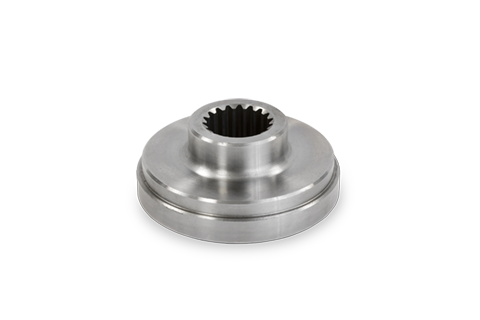

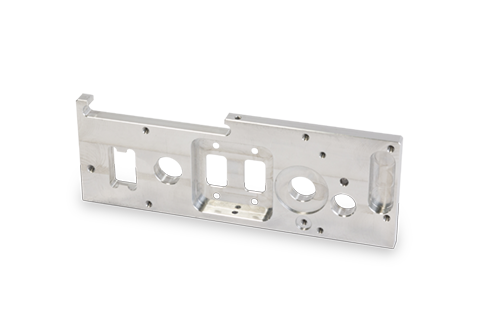

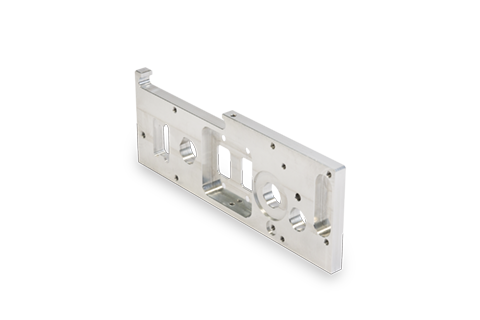

Processing

GLS is processing

A HIGH-QUALITY machine inventory that is constantly expanding

Our machinery and equipment are the jewels in our crown. We have fitted our warehouse with cutting-edge systems, in order to carry out a wide range of processes.

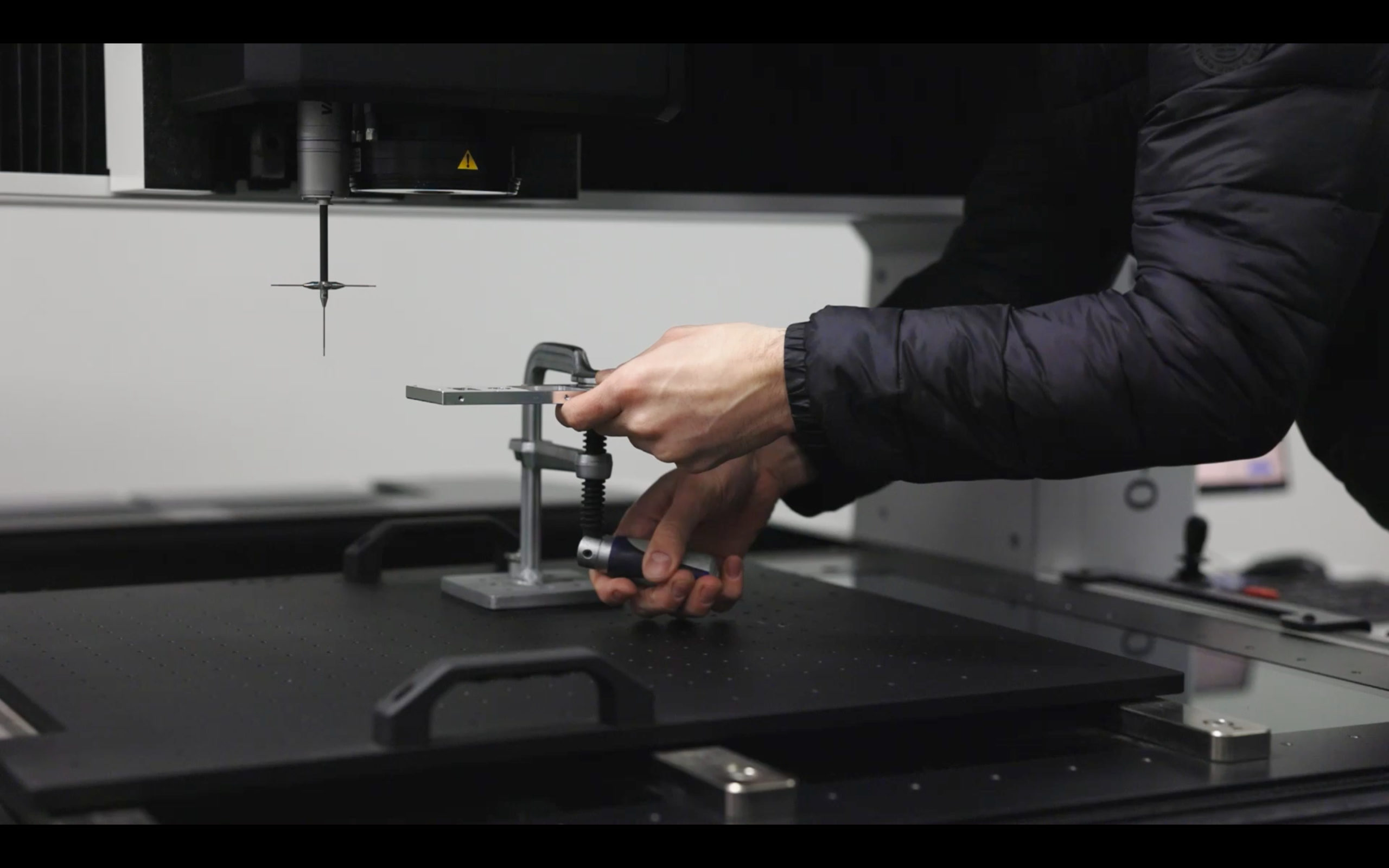

Our latest acquisitions in the field of precision measuring:

ZEISS O-INSPECT – multi-sensor CMM

A multi-sensor measuring machine that allows for the optimal measuring of every single characteristic either optically or via contact in compliance with ISO-10360.

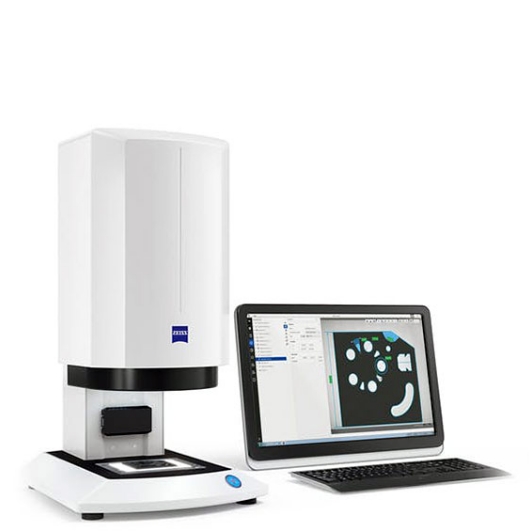

ZEISS O-SELECT – Q-PLUS LABS

A latest generation measuring tool that renders the optical measurement of 2D parts simple and reliable.

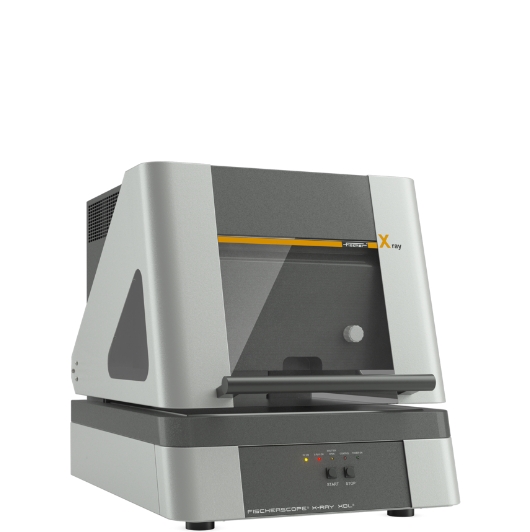

FISCHERSCOPE X-RAY XDL E XDLM

For automated XRF testing; an energy-dispersive X-ray fluorescence spectrometer for the automated analysis of materials and the non-destructive measuring of surface coating thickness.

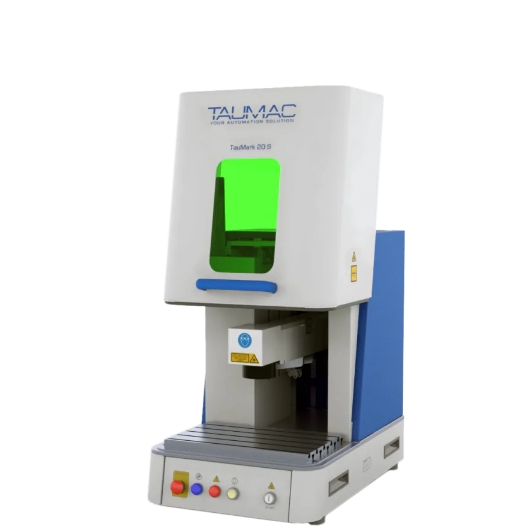

TAUMARK SERIE S / S+ Laser marker and micro-cutter

Laser markers developed for precision marking on any type of small object, providing clear and defined details even on geometrically complex items.

We produce parts by design for a wide range of sectors

Industry

Vehicles

Electromechanics

Medicine

Modula Lift: a new concept in automated warehousing

We have installed a new automatic vertical tray warehouse in our plant that is capable of storing our industrial materials, offering a 90% reduction in the space used and allowing us to optimise our workflows.